- Home

- Shop

- Services

-

Technical

- ECU Identification

- Technical Support

- Hondata Flashpro FK8 Launch Control

- Hondata Flashpro FK8 Traction Control

- How To Correctly Measure Main Bearings

- Line Boring and Main Journals

- Cylinder Head Information - Part 1

- Cylinder Head Information - Part 2

- K24 Test Engine

- K24 Test Engine Part 2

- K24 Test Engine Part 3

- K24 Test Engine Part 4

- K24 Test Engine Part 5

- K24 Test Engine More Midrange Power

- Jackson Racing Supercharger DC5 RSX Diagrams

- Media

- Contact

- Workshop Equipment For Sale

Customer login

Cylinder Head Information - Part 1

When rebuilding an engine for either road or competition use, there are a number of important points to check in the cylinder head before you bolt it back on to your newly rebuilt block, as follows:-

Cylinder Head Face

With combustion pressures in the region of 2000 to 3000 psi, a good seal between the head and the block is essential. Machining both the head face and block face flat with the appropriate surface finish will ensure that the correct seal is achieved. The surface finish is measured in RA (roughness average). For example, Cometic recommend an RA of 50 or finer for a multi layer steel gasket to achieve a proper seal.

Valve Guides and Valves

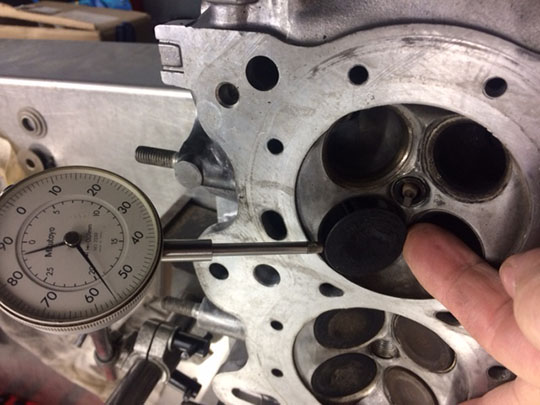

Always check the clearance between the valve guide and the valve stem to ensure that it is within the specification laid out in the factory service manual. If it is a competition or high performance engine you are building, you will likely want to adjust these clearances to suit your application. The easiest way for an enthusiast that does not have a fully equipped workshop is the 'wobble method'. This is undertaken by inserting the valve into the valve guide approximately 10mm from the valve seat, and then setting up a dial indicator on the head of the valve. Once you have set the dial indicator up, move the head of the valve back and forth and take a reading. If the reading is outside the manufacturer’s specification, or what you are looking to achieve in your competition/high performance engine, either the valve guides, valves or both will require replacement.

Types of Valve Guide

Valve guides usually fall into two categories depending on the intended use of the engine.

Race guides are usually made from some form of bronze based material, whereas street guides are usually made from an iron based material. It is important to choose a valve guide material suitable for your application. Bronze guides will only last at best around 10,000 miles in a street application with rockers.

Diamond Honing

It is important that when new valve guides are installed in a high performance application they are diamond honed to give the correct clearance between the valve stem and the valve guide. Unlike regular valve guides, high performance valve guides are sized so that once installed into the cylinder head, the inside diameter is undersize to allow for diamond honing. This is different from regular aftermarket valve guides, which are often fitted with no finishing operation carried out after fitment. Whilst this may be sufficient for an everyday low revving family car, this is not suitable for a high performance/competition engine.

Valve Seats

Even when valve guides are installed correctly, the valve guide centreline and the valve seat will be out of alignment and the valve will no longer seal. To put this into perspective, on a good high performance valve seat you should be looking to achieve alignment in the region of 5microns (0.005mm). Once new valve guides have been installed it is therefore essential to cut the valve seats.

Questions and Answers

What can I gain from having new valve guides installed and valve seats cut to my cylinder head?

Firstly, if your valve guides are worn they will need to be replaced otherwise damage could occur. In a high performance application replacing the valve guides in your cylinder head can increase the performance in a number of ways:

- Reduction of friction

- Increased vacuum in the inlet port

- It will dissipate heat more effectively

- It will allow a better seal between the valve and valve seat resulting in higher compression

- Improvement of airflow through the ports with the use of a more aerodynamic valve guide profile

Secondly, airflow can be improved by cutting the valve seats with alternative angles/radii, un-shrouding the valve in the combustion chamber, or cutting the seat to allow installation of larger valves. Greater valve to piston clearance can also be achieved by cutting the seat deeper if required.

Share this page

Why shop with us?

Value For Money

Worldwide Delivery

Secure On-Line Payments

Browse our expanding range of premium quality CPL Racing products

Terms and Conditions of Trade

Privacy Policy

Returns Policy

© 2026. CPL Racing

CPL Racing is a trading name of Chamberlain Precision Limited

Registration number 4219332

Site By 321-Designs